Izindandatho Zokugqoka zeTungsten Carbide Zomkhakha Kawoyela Negesi

Incazelo emfushane:

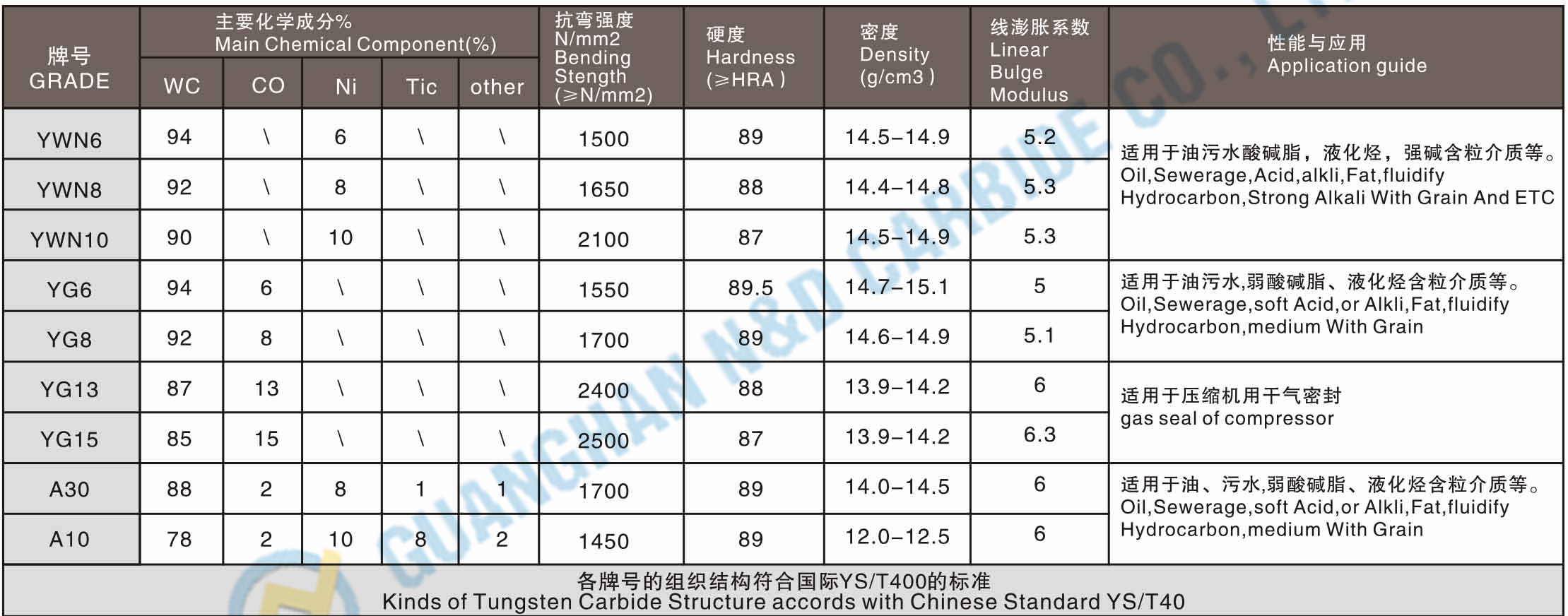

* I-Tungsten Carbide, i-Nickel/Cobalt Binder

* Izithando ze-Sinter-HIP

* Imishini ye-CNC

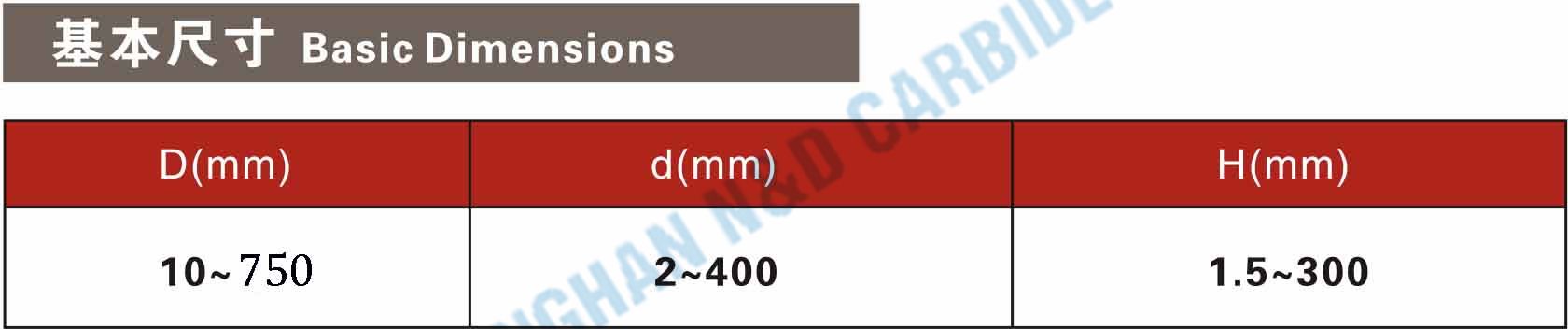

* Ububanzi Bangaphandle: 10-750mm

* I-Sintered, standard eqediwe, kanye ne-mirror lapping;

* Osayizi abengeziwe, ukubekezelelana, amamaki kanye nobuningi kuyatholakala uma ucela.

Indandatho yokugqokwa kwe-tungsten carbide yenzelwe ukuqina okungenakuqhathaniswa ezindaweni ezinomfutho ophezulu, izinga lokushisa eliphezulu, kanye nezokugqwala. Njengomholi ezixazululweni zezinto ezithuthukisiwe, siletha izindandatho zokuvala eziklanywe ngokunemba ezichaza kabusha ukusebenza kwezicelo zezimboni.

Izindandatho zokugqoka ze-Tungsten Carbide zisetshenziswa kabanzi njengezibuko zokuvala ezivalweni zemishini zamaphampu, ama-compressor mixers kanye nama-agitator atholakala ezindaweni zokuhlanza uwoyela, ezimbonini ze-petrochemical, ezimbonini zomanyolo, ezimbonini zobhiya, ezimayini, ezigayweni ze-pulp, kanye nasembonini yemithi. Indandatho yokuvala izofakwa emzimbeni wephampu kanye ne-axle ejikelezayo, bese yakha uphawu oluwuketshezi noma lwegesi ebusweni bokugcina bendandatho ejikelezayo nengashintshi.

Izimo Zohlelo Lokusebenza

- Uwoyela negesi: Imishini yokubhoboza isiqu, amathuluzi okudonsa phansi, kanye nezivalo zamapayipi.

- Ukucubungula Amakhemikhali: Amaphampu, ama-reactor, nama-valve aphatha uketshezi olunamandla.

- Imishini Yezimboni: Ama-compressor, ama-turbine, kanye nezinhlelo ze-hydraulic.

- I-Marine: Imishini yangaphansi kolwandle kanye nezingxenye ezingamelani namanzi anosawoti.

Kukhona ukukhetha okukhulu kosayizi nezinhlobo zendandatho yokugqoka ye-tungsten carbide, singancoma futhi, ukuklama,ukuthuthukisa, ukukhiqiza imikhiqizo ngokwemidwebo nezidingo zamakhasimende.

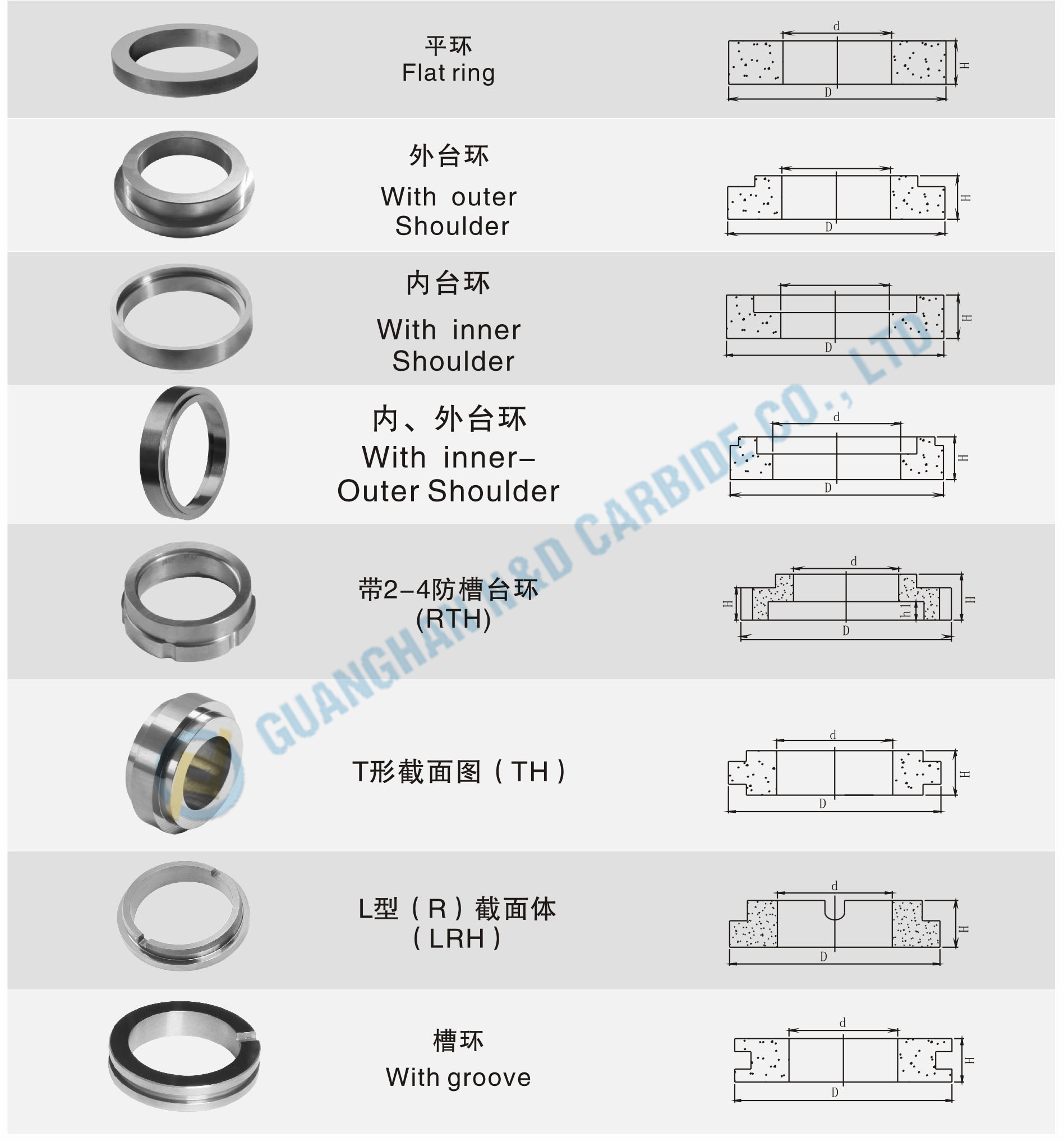

Izindandatho zokugqoka ze-tungsten carbide zakhiwe ngezimo ezahlukahlukene ukuze zivumelane nemishini ehlukene yokusetshenziswa.

Ukuze kube lula kuwe, nansi eminye yezinhlobo ezivamile zendandatho ye-TC:

Ukumelana Nokugqoka Okungalingani

Indandatho yokugqokwa kwe-tungsten carbide idlula insimbi kanye ne-ceramics ezindaweni ezirhabaxa, iqinisekisa ukulahleka okuncane kwezinto ezibonakalayo kanye nokuphila isikhathi eside kwenkonzo. Ubulukhuni bayo obukhulu (Mohs 9-9.5) buyenza ifaneleke kakhulu ezimweni ezihambisana nokushayisana okukhulu.

Ukuvikelwa Kokugqwala

Idizayinelwe ukucubungula amakhemikhali kanye nokusetshenziswa olwandle, indandatho yokugqokwa kwe-tungsten carbide imelana noketshezi olunamandla kanye namanzi anosawoti, ivimbela ukuwohloka kanye nezingozi zokuvuza.

Ukuzinza Kwe-Thermal

Igcina ubuqotho besakhiwo kuze kufike ku-500°C, igcina indandatho yokugqokwa kwe-tungsten carbide iqinile futhi ingenazo izinguquko ngaphansi kokusebenza kwezinga lokushisa eliphezulu.

Isikhathi Sokuphila Esandisiwe

Kunciphisa isikhathi sokungasebenzi kokulungisa ngo-50%+ uma kuqhathaniswa nezivalo ezivamile, kunciphisa izindleko zokusebenza nokukhulisa ukusebenza kahle ezimbonini ezifana nowoyela negesi kanye nezimayini.

Ukwenza ngokwezifiso

Amajiyometri aklanyelwe kanye nokuqedwa kobuso kuthuthukisa indandatho yokugqokwa kwe-tungsten carbide ukuze kuhlangatshezwane nezidingo ezithile, kusukela ekusetshenzisweni ngokunemba kuya ekuphathweni koketshezi olunomfutho ophezulu.

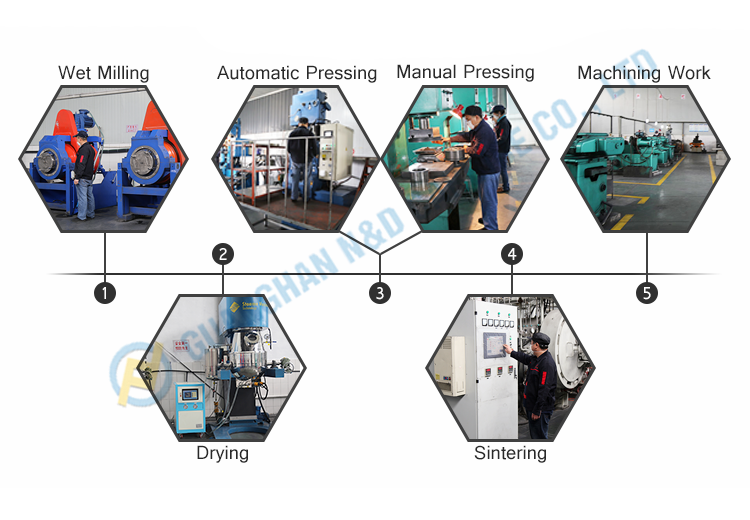

- Ukulungiswa Kwezinto: Impuphu ye-tungsten carbide emsulwa kakhulu ixutshwa ne-cobalt binder ukuze kube nokuqina nokuqina okuhle.

- Ukucindezela Nokuhlikihla: Ukucindezela okuphezulu okulandelwa ukuhlikihla okulawulwayo kuqinisekisa ukubhoboka okuncane kanye nobuningi obukhulu.

- Umshini Oqondile: Ukugaya okulawulwa yikhompyutha kufeza ukunemba kwezinga le-micron ukuze kube nokuvalwa okuphelele.

- Ukwelashwa Komphezulu: Izembozo ezingakhethwa zithuthukisa ukumelana nokugqwala futhi zinciphise ukungqubuzana.

I-Guanghan ND Carbide ikhiqiza izinhlobo eziningi ze-tungsten carbide engagugi futhi engagqwali.

izingxenye.

*Izindandatho zophawu lwemishini

*Ama-Bushings, Imikhono

*Ama-Nozzle e-Tungsten Carbide

*AP| Ibhola kanye nesihlalo

*Isiqu Sokuchoboza, Isihlalo, Amakheji, Idiski, Ukusika Okugelezayo..

*Ama-Tungsten Carbide Burs/Izinduku/Amapuleti/Ama-Strip

*Ezinye izingxenye zokugqoka ze-tungsten carbide ezenziwe ngokwezifiso

-- ...

Sinikeza uhla oluphelele lwamazinga e-carbide kokubili kuma-binder e-cobalt kanye ne-nickel.

Siphatha zonke izinqubo endlini ngokulandela imidwebo yamakhasimende ethu kanye nemininingwane yezinto ezibonakalayo. Ngisho noma ungaboni

Kubhalwe lapha, uma unemibono esizoyikhiqiza.

U: Ingabe uhweba ngenkampani noma umenzi?

A: Singabakhiqizi be-tungsten carbide kusukela ngo-2004. Singahlinzeka ngamathani angu-20 omkhiqizo we-tungsten carbideinyanga. Singakunikeza imikhiqizo ye-carbide eyenziwe ngokwezifiso ngokwezidingo zakho.

Q: Isikhathi sakho sokulethwa singakanani?

A: Ngokuvamile kuzothatha izinsuku eziyi-7 kuya kwezingama-25 ngemuva kokuqinisekiswa kwe-oda. Isikhathi sokulethwa esithile sincike kumkhiqizo othizekanye nobuningi obudingayo.

U: Ingabe ninikeza amasampula? Ingabe amahhala noma ayakhokhiswa?

A: Yebo, singanikeza isampula mahhala kodwa imithwalo ikhokhwa ngamakhasimende.

U. Ingabe uyazihlola zonke izimpahla zakho ngaphambi kokulethwa?

A: Yebo, sizokwenza ukuhlolwa okuphelele kanye nokuhlolwa kwemikhiqizo yethu ye-carbide eqinisiwe ngaphambi kokulethwa.

1. INTENGO YEFIKITHI ;

2. Ukukhiqiza imikhiqizo ye-carbide ye-Focus iminyaka eyi-17 ;

3.lSO kanye nomkhiqizi oqinisekisiwe we-AP|

4. Insizakalo eyenziwe ngokwezifiso ;

5. Ikhwalithi enhle kanye nokulethwa okusheshayo ;

6. Ukushisa kwesithando se-HLP ;

7. Umshini we-CNC ;

8. Umhlinzeki wenkampani i-Fortune 500 ;