Idiski ye-Tungsten Carbide yeValve

Incazelo emfushane:

* I-Tungsten Carbide, i-cobalt/i-Nickel Binder

* Izithando ze-Sinter-HIP

* Imishini ye-CNC

* Ukuguga okugugulekayo

* Isixazululo sokulawula esingcono

* Isevisi eyenziwe ngokwezifiso

I-alloy eqinile ye-tungsten carbide iklanyelwe ngqo ukumelana nokugqwala, ukuguguleka, ukuguguleka, ukushibilika, ukuguguleka okushelelayo kanye nomthelela kokubili ukusetshenziswa kwemishini yasogwini kanye neyasogwini kanye neyasogwini kanye neyangaphansi kolwandle.

I-Tungsten carbide iyinhlanganisela yamakhemikhali angaphili equkethe inani lama-athomu e-tungsten ne-carbon. I-Tungsten carbide, eyaziwa nangokuthi “i-cemented carbide”, “i-hard alloy” noma “i-hardmetal”, uhlobo lwezinto ze-metallurgic eziqukethe i-tungsten carbide powder (ifomula yamakhemikhali: i-WC) kanye nezinye izinto ezihlanganisa (i-cobalt, i-nickel, njll.).

Ingacindezelwa futhi yenziwe ibe yizimo ezenziwe ngokwezifiso, ingagaywa ngokunemba, futhi ingashintshwa noma ixhunywe kwezinye izinsimbi. Izinhlobo ezahlukene kanye namazinga e-carbide angaklanywa njengoba kudingeka ukuze asetshenziswe ekusetshenzisweni okuhlosiwe, okuhlanganisa imboni yamakhemikhali, uwoyela negesi kanye nolwandle njengamathuluzi okumba kanye nokusika, isikhunta kanye nodayi, izingxenye zokuguguleka, njll.

I-tungsten carbide isetshenziswa kabanzi emishinini yezimboni, amathuluzi angagugi kanye nokulwa nokugqwala. I-tungsten carbide iyinto engcono kakhulu yokumelana nokushisa nokuqhekeka kuzo zonke izinto eziqinile.

Idiski yevalvu yepuleti le-Tungsten Carbide isetshenziswa kabanzi ku-oyili negesi ngenxa yokumelana nokuguguleka okuphezulu, ukumelana nokugqwala okuphezulu.

Amadiski e-tungsten carbide asetshenziswa kabanzi kuma-valve. Amadiski amabili aseduze ngalinye liqukethe imigodi yokunemba ye-twp (i-orifice). Idiski engaphambili iyantanta ngokumelene nediski engemuva idala isikhombimsebenzisi esihlanganisiwe futhi iqinisekisa uphawu oluhle. I-valve yohlobo lwediski isebenzisa amadiski amabili e-Tungsten Carbide anezimbobo ze-geometry ethile. Idiski engenhla ijikeleziswa uma kuqhathaniswa nediski engezansi (ngesandla noma nge-actuator) eshintsha usayizi we-orifice. Amadiski ajikeleziswa ngama-degree angu-180 phakathi kwesikhundla esivulekile nesivaliwe. Ngaphezu kwalokho, izindawo ezigobile zamadiski zenzelwe ukunikeza uphawu oluhle.

I-Guanghan ND Carbide ikhiqiza izinhlobo eziningi ze-tungsten carbide engagugi futhi engagqwali.

izingxenye.

*Izindandatho zophawu lwemishini

*Ama-Bushings, Imikhono

*Ama-Nozzle e-Tungsten Carbide

*Ibhola le-API kanye nesihlalo

*Isiqu Sokuchoboza, Isihlalo, Amakheji, Idiski, Ukusika Okugelezayo..

*Ama-Tungsten Carbide Burs/Izinduku/Amapuleti/Ama-Strip

*Ezinye izingxenye zokugqoka ze-tungsten carbide ezenziwe ngokwezifiso

-- ...

Sinikeza uhla oluphelele lwamazinga e-carbide kokubili kuma-binder e-cobalt kanye ne-nickel.

Siphatha zonke izinqubo endlini ngokulandela imidwebo yamakhasimende ethu kanye nemininingwane yezinto ezibonakalayo. Ngisho noma ungaboni

Kubhalwe lapha, uma unemibono esizoyikhiqiza.

U: Ingabe uhweba ngenkampani noma umenzi?

A: Singabakhiqizi be-tungsten carbide kusukela ngo-2004. Singahlinzeka ngamathani angu-20 omkhiqizo we-tungsten carbide

inyanga. Singakunikeza imikhiqizo ye-carbide eyenziwe ngokwezifiso ngokwezidingo zakho.

Q: Isikhathi sakho sokulethwa singakanani?

A: Ngokuvamile kuzothatha izinsuku eziyi-7 kuya kwezingama-25 ngemuva kokuqinisekiswa kwe-oda. Isikhathi sokulethwa esithile sincike kumkhiqizo othize

kanye nobuningi obudingayo.

U: Ingabe ninikeza amasampula? Ingabe amahhala noma ayakhokhiswa?

A: Yebo, singanikeza isampula mahhala kodwa imithwalo ikhokhwa ngamakhasimende.

U. Ingabe uyazihlola zonke izimpahla zakho ngaphambi kokulethwa?

A: Yebo, sizokwenza ukuhlolwa okuphelele kanye nokuhlolwa kwemikhiqizo yethu ye-carbide eqinisiwe ngaphambi kokulethwa.

1. INTENGO YASEFIKIRI;

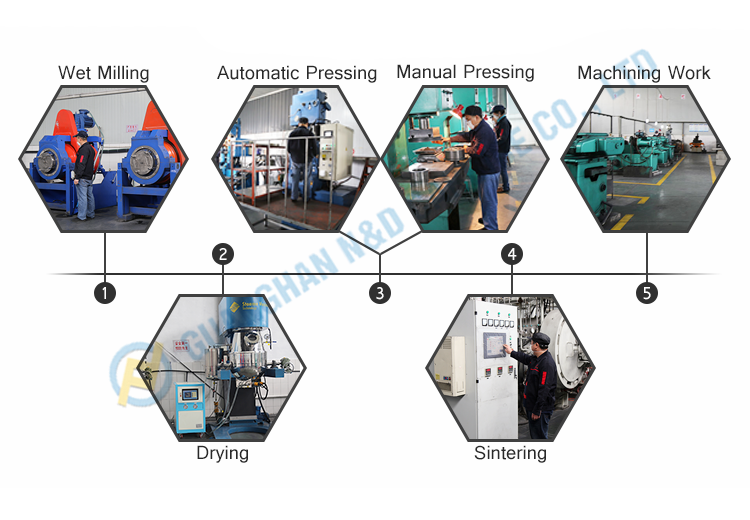

2. Ukukhiqiza imikhiqizo ye-carbide egxile iminyaka eyi-17;

3.lSO kanye nomkhiqizi oqinisekisiwe we-AP|;

4. Insizakalo eyenziwe ngokwezifiso;

5. Ikhwalithi enhle kanye nokulethwa okusheshayo;

6. Ukushisa isithando somlilo se-HLP;

7. Umshini wokugaya we-CNC;

8. Umhlinzeki wenkampani i-Fortune 500.