Indandatho Yophawu Lwe-Tungsten Carbide Eyenziwe Ngokwezifiso Yezimpawu Zomshini

Incazelo emfushane:

* I-Tungsten Carbide, i-Nickel/Cobalt Binder

* Izithando ze-Sinter-HIP

* Imishini ye-CNC

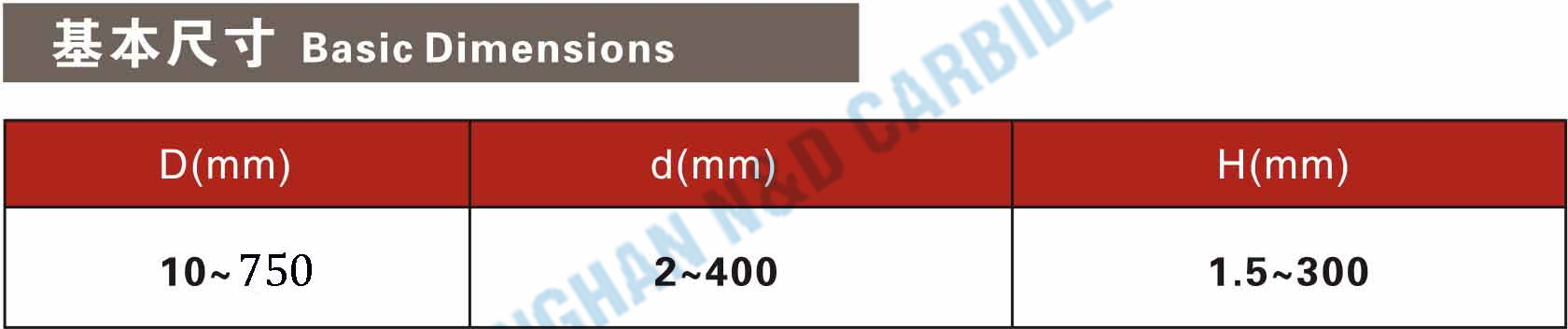

* Ububanzi Bangaphandle: 10-800mm

* I-Sintered, standard eqediwe, kanye ne-mirror lapping;

* Osayizi abengeziwe, ukubekezelelana, amamaki kanye nobuningi kuyatholakala uma ucela.

Sethula indandatho yethu yokuvala ye-Tungsten Carbide eyenzelwe wena, ikhambi eliphelele lokuqinisekisa ukusebenza kahle kanye nokuphila isikhathi eside ekusetshenzisweni kokuvala kwemishini. Yenziwe ngokunemba nangobuchwepheshe, amasongo ethu okuvala aklanyelwe ukumelana nezimo zezimboni ezidinga kakhulu, enikeza ukumelana nokuguguleka okumangalisayo kanye nokuthembeka.

Izindandatho zethu zokuvala ze-Tungsten Carbide zenziwe ngokwezifiso ukuze zihlangabezane nezidingo ezithile zezimbozo zomshini, okuqinisekisa ukulingana okuphelele nokuhlanganiswa okungenamthungo. Ubulukhuni obuphezulu kanye nokuqina kwe-tungsten carbide kwenza kube yinto efanelekile yezimbozo zokuvala, okunikeza ukumelana okuhle kakhulu nokuguguleka, ukugqwala, kanye nokushisa okuphezulu. Lokhu kusho ukuthi izindandatho zethu zokuvala zingavimbela ngempumelelo ukuvuza futhi zigcine isimbozo siqinile ngisho nasezimweni ezinzima kakhulu, ekugcineni kuncishiswe izindleko zokulungisa kanye nesikhathi sokungasebenzi.

Ngokuzibophezela kwethu ekhwalithini nasekusunguleni izinto ezintsha, sisebenzisa amasu okukhiqiza athuthukile ukukhiqiza izindandatho zokuvala ezidlula amazinga embonini. Indandatho ngayinye ihlolwa ngokucophelela ukuqinisekisa ukunemba nokuvumelana, ukuqinisekisa ukuthi amakhasimende ethu athola umkhiqizo osezingeni eliphezulu.

Ngaphezu kokusebenza kwazo okuhle kakhulu, izindandatho zethu ze-Tungsten Carbide Seal Rings ezenziwe ngokwezifiso nazo zingenziwa ngokwezifiso kakhulu, okuvumela izixazululo ezenzelwe wena ukuhlangabezana nezidingo ezithile zohlelo lokusebenza. Kungakhathaliseki ukuthi usayizi ohlukile, ukuma, noma izidingo ezikhethekile zokumboza, sinekhono lokuletha izindandatho ze-seal ezenziwe ngokwezifiso ezihambisana kahle nemininingwane yamakhasimende ethu.

Ngaphezu kwalokho, ukuzinikela kwethu ekwanelisekeni kwamakhasimende kudlulela ngale komkhiqizo ngokwawo. Sinikeza ukwesekwa okuphelele kanye nobuchwepheshe bobuchwepheshe ukusiza amakhasimende ethu ekukhetheni indandatho yokuvala efaneleke kakhulu yezicelo zawo, kanye nokunikeza isiqondiso mayelana nemikhuba emihle yokufaka nokulungisa.

Ekuphetheni, izindandatho zethu ze-Tungsten Carbide Seal Rings zethu ezenziwe ngokwezifiso ze-Mechanical Seals zinikeza ukuqina okungenakuqhathaniswa, ukuthembeka, kanye nezinketho zokwenza ngokwezifiso, okwenza kube ukukhetha okuhle kakhulu kwezimboni lapho izixazululo zokuvala ezithembekile zibaluleke kakhulu. Thembela kubuchwepheshe bethu kanye nesipiliyoni sethu sokuletha izindandatho zokuvala ezisebenza kahle kakhulu kunezilindelwe futhi zinegalelo ekusebenzeni okungenamthungo kwezinhlelo ze-mechanical.

I-Tungsten carbide (TC) isetshenziswa kabanzi njengemibuso noma izindandatho zesivalo ezinokumelana nokugqoka, amandla aphezulu okuqhekeka, ukuhanjiswa okuphezulu kokushisa, kanye nokwandiswa okuncane kokushisa okusebenza kahle. Indandatho yesivalo se-tungsten carbide ingahlukaniswa ibe yindandatho yesivalo ejikelezayo kanye nendandatho yesivalo esingaguquki. Izinhlobo ezimbili ezivame kakhulu zobuso/izindandatho zesivalo se-tungsten carbide yi-cobalt binder kanye ne-nickel binder.

Izivalo ze-tungsten carbide mechanical seals zisetshenziswa kakhulu kupompo yoketshezi ukuze zithathe indawo yesivalo se-gland esipakishiwe kanye nesivalo sezindebe. Isivalo se-tungsten carbide mechanical seal Ipompo enophawu lwemishini isebenza kahle kakhulu futhi ngokuvamile isebenza ngokuthembeka isikhathi eside.

Ngokwesimo sazo, lezo zimbozo zibizwa nangokuthi izindandatho zokuvala ze-tungsten carbide mechanical. Ngenxa yobuhle bezinto ze-tungsten carbide, izindandatho zokuvala ze-tungsten carbide mechanical zibonisa ubulukhuni obukhulu, futhi okubaluleke kakhulu ukuthi zimelana nokugqwala nokukhuhla kahle. Ngakho-ke, izindandatho zokuvala ze-tungsten carbide mechanical zisetshenziswa kabanzi kunezimbozo zezinye izinto.

I-tungsten carbide mechanical seal inikezwa ukuvimbela uketshezi olupompelwayo ukuthi lungaphumi eceleni kwe-drive shaft. Indlela yokuvuza elawulwayo iphakathi kwezindawo ezimbili eziyisicaba ezihlotshaniswa ne-shaft ejikelezayo kanye ne-housing ngokulandelana. Igebe lendlela yokuvuza liyahlukahluka njengoba ubuso bubhekene nomthwalo wangaphandle ohlukahlukene ovame ukuhambisa ubuso buhlobene.

Imikhiqizo idinga ilungiselelo lokuklama indlu yeshafti elihlukile uma kuqhathaniswa nalelo lolunye uhlobo lwe-mechanical seal ngoba i-mechanical seal iyilungiselelo eliyinkimbinkimbi kakhulu futhi i-mechanical seal ayinikezi ukwesekwa ku-shafti.

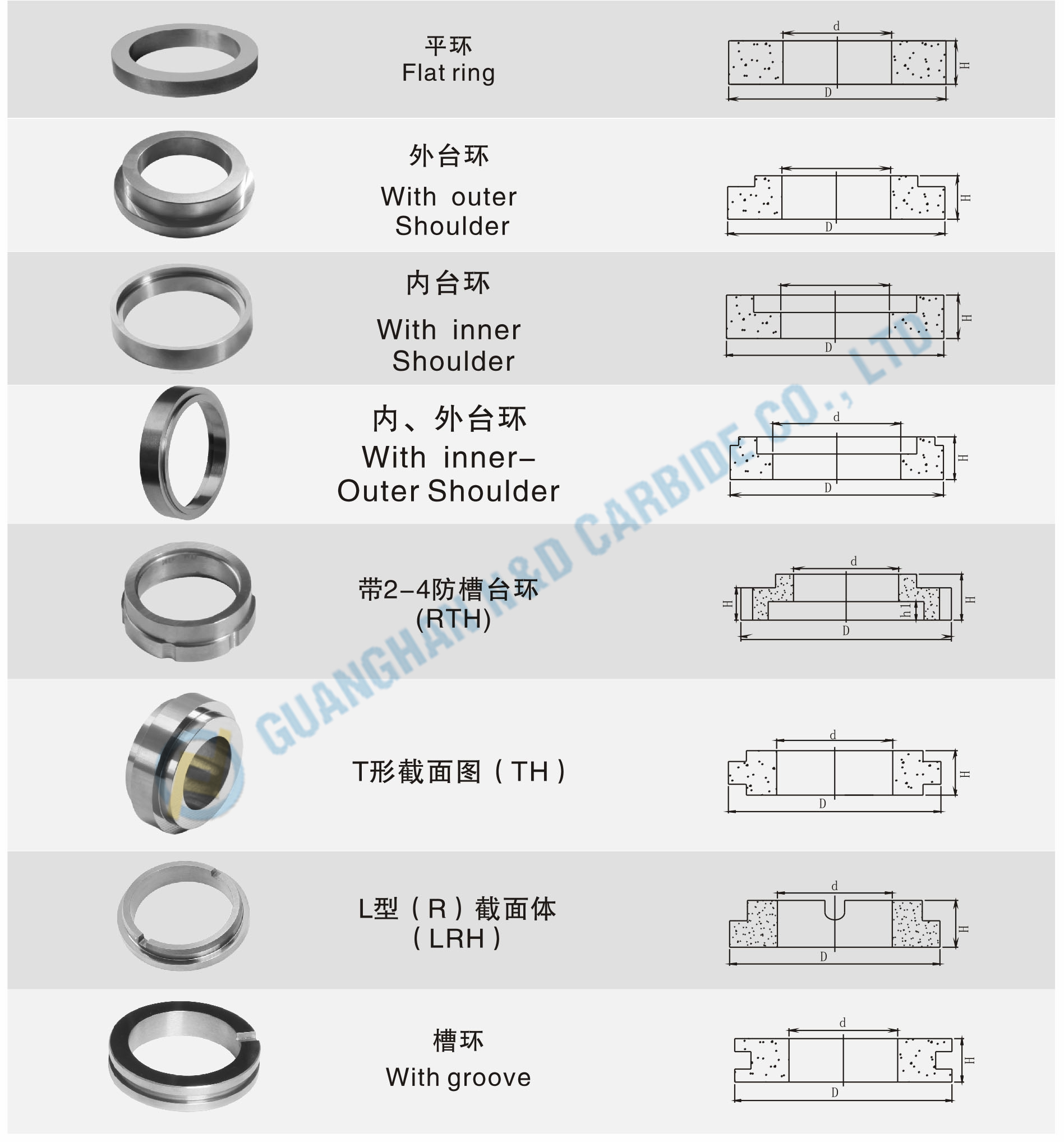

Amasongo okuvala omshini we-tungsten carbide afika ngezinhlobo ezimbili eziyinhloko:

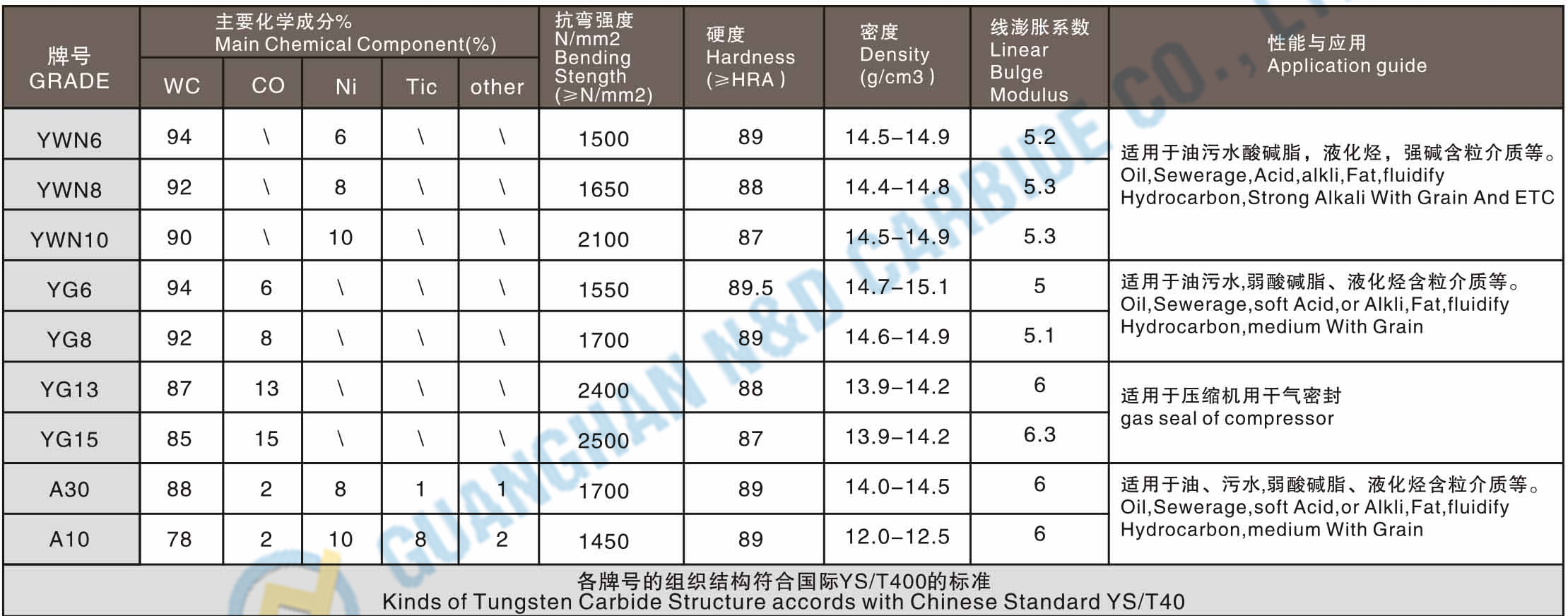

Ukubopha i-Cobalt (ukusetshenziswa kwe-ammonia kufanele kugwenywe)

Ukubopha nge-nickel (Kungasetshenziswa ku-ammonia)

Ngokuvamile izinto zokubopha ezingu-6% zisetshenziswa emasongweni okuvala e-tungsten carbide mechanical, nakuba kutholakala ububanzi obuningi. Amasongo okuvala e-tungsten carbide mechanical ahlanganiswe ne-nickel avame kakhulu emakethe yamaphampu amanzi angcolile ngenxa yokumelana kwawo nokugqwala okuthuthukisiwe uma kuqhathaniswa nezinto eziboshwe yi-cobalt.

Amasongo okuvala e-Tungsten Carbide asetshenziswa kabanzi njengezibuko zokuvala ezivalweni zemishini zamaphampu, ama-compressor mixers kanye nama-agitator atholakala ezindaweni zokuhlanza uwoyela, ezimbonini ze-petrochemical, ezimbonini zomanyolo, ezimbonini zobhiya, ezimayini, ezigayweni ze-pulp, kanye nasembonini yemithi. Indandatho yokuvala izofakwa emzimbeni wephampu kanye ne-axle ejikelezayo, bese yakha uphawu oluwuketshezi noma lwegesi ebusweni bokugcina bendandatho ejikelezayo nengashintshi.

Izindandatho zokuvala ze-tungsten carbide, njengomkhiqizo we-alloy owenziwe ngezinqubo ze-powder metallurgy, zinobubanzi obubanzi nobalulekile bezicelo. Ngezansi kunencazelo eningiliziwe ngobubanzi bezicelo zazo:

Izimboni Zokukhipha Amafutha Nezamakhemikhali

Ezimbonini zokukhipha uwoyela kanye namakhemikhali, izindandatho zokuvala i-carbide zithandwa kakhulu ngenxa yokumelana kwazo okuphawulekayo nokuguguleka, ukumelana nokugqwala, kanye nokumelana nokushayisana. Lezi zakhiwo zibenza bakwazi ukusebenza ngokuqina isikhathi eside ezindaweni zokusebenza ezinzima, zivimbele ngempumelelo ukuvuza okuphakathi nokuqinisekisa ukuphepha kokukhiqiza. Izindandatho zokuvala i-carbide zivame ukusetshenziswa njengezingxenye ezibalulekile zokuvala kumaphampu ahlukahlukene, ama-compressor, ama-valve, kanye neminye imishini.

Umkhakha Wokukhiqiza Imishini

Izindandatho zokuvala i-carbide nazo zidlala indima ebalulekile emkhakheni wokukhiqiza imishini. Zisetshenziswa kabanzi eziqondisweni zamasilinda kawoyela, emishinini ehlukahlukene yokukhiqiza, kanye nemishini ezenzakalelayo yemishini, njengezimbozo zezingxenye ze-telescopic, oscillating, sliding, golding, kanye ne-rounding. Ubulukhuni obuphezulu kanye nokumelana nokuguguleka kwezindandatho zokuvala i-carbide kwandisa kakhulu isikhathi sokuphila kwemishini, kunciphisa ukugcinwa kanye nemvamisa yokushintsha, kanye nezindleko zokusebenza eziphansi zamabhizinisi.

Imboni Yezokuthutha

Izindandatho zokuvala i-carbide zisesikhundleni esibalulekile embonini yezokuthutha. Zikhona ezimotweni, ezithuthuthwini, nasemishinini eyahlukahlukene yokuphatha kanye neyokulima, lapho izingxenye eziningi ezishelelayo nezijikelezayo zidinga izindandatho ezinokwethenjelwa. Ukusebenza kokuvala kwalezi zingxenye kuthinta ngqo ukuphepha nokuthembeka kwezimoto. Izindandatho zokuvala i-carbide, ngokusebenza kwazo kokuvala okuvelele kanye nokumelana nokuguguleka, zinikeza isivikelo esithembekile salezi zingxenye.

Imboni Yezinsimbi

Izindandatho zokuvala i-carbide nazo zidlala indima ebalulekile embonini yezinsimbi. Njengoba izinsimbi zivame ukusebenza ezindaweni eziqondile nezizinzile, izidingo zezingxenye zokuvala ziphakeme kakhulu. Izindandatho zokuvala i-carbide, ngokunemba kwazo okuphezulu, ukumelana nokugqwala, kanye nokumelana nokuguguleka, zigcwalisa izidingo eziqinile zezinsimbi zezingxenye zokuvala.

Ezinye Izinkambu

Ngaphezu kwalokho, izindandatho zokuvala i-carbide zisetshenziswa kabanzi emikhakheni ehlukahlukene njengogesi, i-metallurgy, kanye nokucubungula ukudla. Embonini yamandla, zisetshenziselwa imishini yokuvala ekukhiqizeni ugesi; kwe-metallurgy, zisetshenziselwa ukuvala ngaphansi kwezimo zokushisa okuphezulu kanye nokucindezela okuphezulu; futhi ekucubungulweni kokudla, ukumelana kwazo nokugqwala kanye nezakhiwo zokuhlanzeka kuzenza zibe yizingxenye ezibalulekile emigqeni yokukhiqiza ukudla.

Ngamafuphi, izindandatho zokuvala i-carbide, ngokusebenza kwazo okuphezulu kanye nobubanzi bokusetshenziswa okubanzi, zidlala indima ebalulekile ezimbonini zanamuhla. Njengoba ubuchwepheshe buqhubeka nokuthuthuka futhi izinhlelo zokusebenza ziqhubeka nokukhula, amathuba emakethe ezindandatho zokuvala i-carbide azothembisa kakhulu.

Kukhona ukukhetha okukhulu kosayizi nezinhlobo zendandatho yesicaba se-tungsten carbide flat, singancoma futhi, siklame, sithuthukise, sikhiqize imikhiqizo ngokwemidwebo nezidingo zamakhasimende.

I-Guanghan ND Carbide ikhiqiza izinhlobo eziningi ze-tungsten carbide engagugi futhi engagqwali.

izingxenye.

*Izindandatho zophawu lwemishini

*Ama-Bushings, Imikhono

*Ama-Nozzle e-Tungsten Carbide

*Ibhola le-API kanye nesihlalo

*Isiqu Sokuchoboza, Isihlalo, Amakheji, Idiski, Ukusika Okugelezayo..

*Ama-Tungsten Carbide Burs/Izinduku/Amapuleti/Ama-Strip

*Ezinye izingxenye zokugqoka ze-tungsten carbide ezenziwe ngokwezifiso

-- ...

Sinikeza uhla oluphelele lwamazinga e-carbide kokubili kuma-binder e-cobalt kanye ne-nickel.

Siphatha zonke izinqubo endlini ngokulandela imidwebo yamakhasimende ethu kanye nemininingwane yezinto ezibonakalayo. Ngisho noma ungaboni

Kubhalwe lapha, uma unemibono esizoyikhiqiza.

U: Ingabe uhweba ngenkampani noma umenzi?

A: Singabakhiqizi be-tungsten carbide kusukela ngo-2004. Singahlinzeka ngamathani angu-20 omkhiqizo we-tungsten carbide

inyanga. Singakunikeza imikhiqizo ye-carbide eyenziwe ngokwezifiso ngokwezidingo zakho.

Q: Isikhathi sakho sokulethwa singakanani?

A: Ngokuvamile kuzothatha izinsuku eziyi-7 kuya kwezingama-25 ngemuva kokuqinisekiswa kwe-oda. Isikhathi sokulethwa esithile sincike kumkhiqizo othize

kanye nobuningi obudingayo.

U: Ingabe ninikeza amasampula? Ingabe amahhala noma ayakhokhiswa?

A: Yebo, singanikeza isampula mahhala kodwa imithwalo ikhokhwa ngamakhasimende.

U. Ingabe uyazihlola zonke izimpahla zakho ngaphambi kokulethwa?

A: Yebo, sizokwenza ukuhlolwa okuphelele kanye nokuhlolwa kwemikhiqizo yethu ye-carbide eqinisiwe ngaphambi kokulethwa.

1. INTENGO YEFIKITHI ;

2. Ukukhiqiza imikhiqizo ye-carbide ye-Focus iminyaka eyi-17 ;

3.lSO kanye nomkhiqizi oqinisekisiwe we-AP|

4. Insizakalo eyenziwe ngokwezifiso ;

5. Ikhwalithi enhle kanye nokulethwa okusheshayo ;

6. Ukushisa kwesithando se-HLP ;

7. Umshini we-CNC ;

8. Umhlinzeki wenkampani i-Fortune 500.